TECHASE® MULTI-PLATE SCREW PRESS

A MOST ADVANCED SLUDGE DEWATERING EQUIPMENT

TECHASE are always focusing on independent technology innovation of themselves.Under the cooperation with Tongji University, TECHSE have successfully developed the new generation of sludge dewatering technology -Techase® multi-plate screw press, a screw type sludge dehydrator that is much more advanced in very aspects than belt presses, centrifues, plate-and-frame filter presses, etc. It features clogging-free, wide range of applications, low energy consumption, simple operation & maintenance.

It has solved several technical problems of other similar sludge dewatering equipment including belt presses, centrifuge machines, plate-and-frame filter press have, which are frequent clogging, low concentration sludge / oil sludge treatment failure, high energy consumption and complicated operation etc.

Factors including concurrent water-power, thin layer dewatering, proper pressure and dewatering path extension etc. were applied by the dewatering mechanism of Techase ® multi-plate screw press. Lower energy / water consumption and longer service life can realized without changing the properties of the feed materials and with high efficiency.

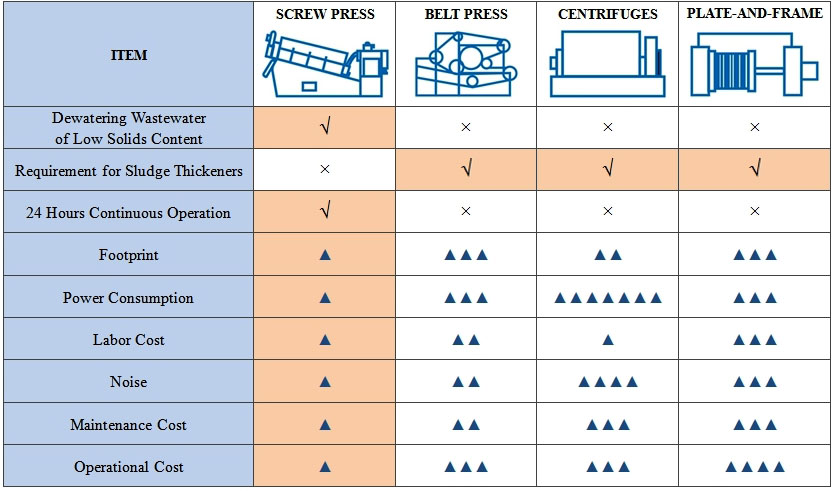

Multi-plate Screw Press VS Belt Presses, Centrifuges, Plate-and-frame Filter Presses

Applications

Techase® multi-plate screw press can be widely used in municipal waste water treatment engineerings as well as the industrial wastewater treatment systems such as petrochemical processing, light industry, chemical fiber, paper-making, pharmacy and leather etc. The multi-plate screw press, as proven by the practical applications, can help to make considerable economic and social benefits for customers.

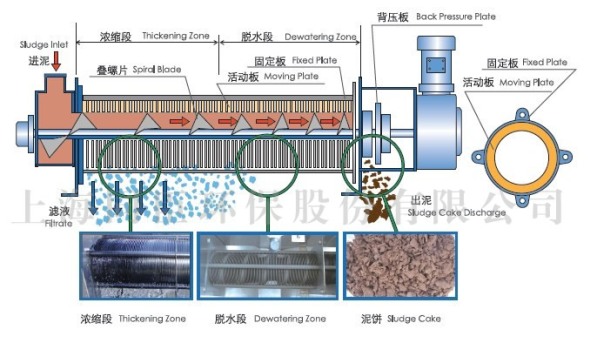

Working Principle

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

Patents

Techase constantly focus on innovation & improvements of our products to meet the requirements of the market and provide our customers with products of reliability and high performance. So far, we've got tens of patents and varieties of pending technologies on Techase® Multi-plate Screw Press.