- Home

- About Techase

Company Profile

A worldwide leading company in solid-liquid

separation of industrial & municipal wastewater.

R&D

Techase always keep eyes on independent

technology research and innovation and

Ability

Factory Shanghai & Factory Jiangsu,

Make Quality Perfection More Perfect

Honors

Awarded and honored by clients,

governments and society.

Support

More and More Supports

Attention from Government

Techase Culture

Quality Foremost, Technology Thirst, Environment First

Diligence Integrity Development Innovation

Techase History

Founded on 8th August, 2008, Techase Creating A Green Future

- News & Events

News and Events

Learn All Latest News of

Industry and Techase

Techase Events

Get Company News At First Time

Industry News

Get Industry News & Trend

Techase Video

Learn More About Techase Via Videos

- Systems & Products

Solutions

Products

Sludge Treatment

Advanced Dewatering

higher in efficiency,more excellent in performance

Wastewater Treatment

Core Fiber Cloth Filtration &

P Removal Technology

Piling Slurry Dewatering

Advanced Fast Drilling

Mud Dewatering Solutions

Oil Tank Slurry Discharging

New Setting Tank Slurry Discharging System

Discharging System

Black & Odorous Water

Economic IDOC Diatom

Water Remediation

Multi-plate Screw Press

First Brand, Top Sales,

Most Installations

Low Temperature Sludge Dryer

Over 70% of

sludge reduction capacity

Membrane Bioreactor(MBR)

Small footprint,

sludge reduction capacity

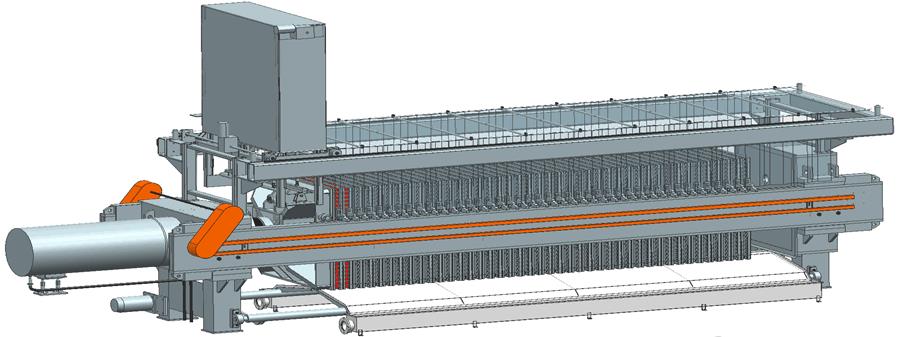

KS Fast Filter Press

Continuous Sludge Feeding and

Filtration Operation

Elaspress Filter Press

3 Times Pressure, 4 Times Efficiency

Fiber Cloth Filter

Second Generation Fiber Cloth

SS Removing Filte

River Dredging Slurry

Special Efficient River

Dredging Sludge Dewatering Filter Press

Others

Sludge Thickener

Automatic Polymer Station,

Efficient Coagulants

Oil Tank Slurry Discharging...

- Industry Solutions

Municipal

Whole-process

Upgrading, cyanobacteria

River&Lake

Rivers dredging

China-Germany cooperation

Building Slurry

Reduction treatment

Improving treatment efficiency

Petrochem

Treatment of oily sludge

Sludge discharge and treatment

Medicine

Filtration separation

Sludge reduction

Papermaking

Pulp dewatering

Wastewater treatment

Mining&Metallurgy

Kaolin production

The cleaned coal, non-ferrous metals

Fruit&Vegetable

Canned products

Vegetable processing

Animal Husbandry

Solid and liquid separation

Comprehensive treatment

Food&Beverage

Juice drinks slag removal

Alcohol dewatering

Slaughtering

New type

High efficiency ,Low cost

Printing&Leather

Deep dewatering

Hazardous waste reduction

Mechatronics

Mortar cutting liquid recovery

Mechanical processing

Others

Contact us

Tel: 400-021-2011.

- Services Center

Model Selection

Select Models through Model List

or Contact Us for Support

Download Center

Technical Documents

Download

Typical Cases

On Site Installation

Visiting Cases Available

Service

Service

FAQs

FAQ about Techase’s Products

- Join Techase

Talent Strategy

Develop Together with Techase

Recruitment

Learn More Our Latest Talent Plant.

Staff Activities

We are a young team with passion,

dreams, perseverance and sharing.

Employee Benefits

Techase Provide You A Stage of Limitless Possibilities

with Benefits & Training

Business Cooperation

Look Forward To Your Joining Us

- Contact Us

Contact

TEL:+86-21-65988709 / 35183635

FAX:+86-21-65988179

Email: Overseas_business@techase.com

Map

Website Map For You

Mobile

Use Your Mobile

Device to Learn What’s New about Techase

- Products

- Multi Plate Screw Press

- Low Temperature Sludge Dryer

- Membrane Bioreactor(MBR)

- High Pressure Filter Press

- KS Fast Filter Press

- Vertical Fiber Cloth Filter

- River Dredging Filter Press

- Sludge Thickening Press

- Solutions

- Sludge Solutions

- Wastewater Solutions

- Piling Slurry Dewatering

- Oil Tank Slurry Dewatering

- Black Odorous Water Solution

Applications:

Techase’s KS fast filter press can be widely used in a huge variety of different applications, from sludge dewatering sections of municipal WWTP, water treatment plant, to industrial solid liquid separation occasions, etc.

- Municipal Waste Sludge Dewatering

- Food Industry

- Brewery Industry

- Pharmaceutical Industry

- Coal & Mine Industry

- Printing And Dyeing Industry

- Papermaking Industry

- Channel Cleanout

- Other Industries

- Continuous Sludge Feeding and Filtration Operation

- Pulsed Press, Producing Instantaneous High Pressure and Pressure Gradient

- Rigid High Pressure Filter Plate

- New Air Blowing Cake Washing Method

- High Filtration Pressure

- Short Working Cycle

- Reduce Footmark By 30%

- Invisible Flow Design

- Less Auxiliary Facilities

- High Automation Level

- High Pressure Plunger Pump

- Resistant To Wear And Corrosion

- High Efficiency, Low Energy Consumption

- Short Feeding Time, Low Maintenance Cost

- Low Operating Cost

- Only Need To Replace Filter Cloth

- About Techase

- Company Profile

- R&D and Innovation

- Production Ability

- Honors & Awards

- Government Support

- Techase Culture

- Techase History

- Products

- Multi Plate Screw Press

- Low Temperature Sludge Dryer

- Membrane Bioreactor(MBR)

- High Pressure Filter Press

- KS Fast Filter Press

- Vertical Fiber Cloth Filter

- River Dredging Filter Press

- Sludge Thickening Press

- Solutions

- Sludge Solutions

- Wastewater Solutions

- Piling Slurry Dewatering

- Oil Tank Slurry Dewatering

- Black Odorous Water Solution

- Industry Solutions

- Municipal

- Fruit&Vegetable

- Petrochem

- Food&Beverage

- Building Slurry

- Papermaking

- Medicine

- Printing&Leather

- Animal Husbandry

- Slaughtering

- River&Lake

- Mining&Metallurgy

- Mechatronics

- Others