Due to the smart structure, advanced design and accurate manufacturing, Techase® multi-plate screw press (MSP) has following features:

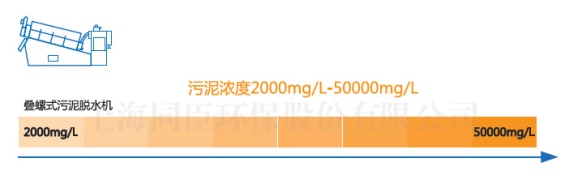

Special pre-concentrating device, wide feed solids concentration: 2000mg/L-50000mg/L

The dewatering part of MSP consists of a thickening zone and a dewatering zone. In addition, a special pre-concentrating device is mounted inner the flocculation tank. Therefore, the wastewater with rather low solids content is not a problem to MSP. The applicable feed solids concentration can be as very wide as 2000mg/L-50000mg/L.

Since MSP can be used directly to concentrate and dewater the low-solid sludge from aeration tanks or secondary clarifiers, the users don't have to build a thickening tank or a storage tank any more while they have to when using other types of sludge dehydrators, especially the belt filter presses. Then significant civil engineering cost and floor area are saved.

Furthermore, the phosphorus emission problem caused by aeration tanks or secondary clarifiers can be well prevented.

Fixed/moving rings replacing filter cloths, self-cleaning, clogging-free

As MSP using fixed rings and moving rings as filter media instead of filter cloths makes it especially good at treating oily sludge when compared with other types similar sludge dehydrator. The moving rings rorate up and down to the fixed rings when the gaps between them are cleand to prevent from clogging.

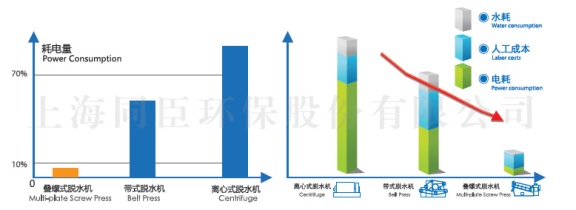

Low-speed rotating, low noise, low energy consumption - only 1/10 of belt filter presses and 1/20 of centrifuges

MSP doesn't need any big supporting equipment such as rollers to work with. The rotating speed is as low as only 2-4 r/min. As a result, it can realize water-saving, energy saving and low noise. The average energy consumption is only 0.01-0.1kwh/kg-DS, only 1/10 as that of belt filter presses and 1/20 as that of centrifugal machines .

Full-automatic control, simple operation and management

The structure of MSP is very compact. The flocculation part, dewatering part and the control cabinet are mounted very tight. All the processes can be operated automatically via the control cabinet.