River and Lake Comprehensive Management Solution

1. According

to the pollution situation and water quality of the river channel, separate the

pollutants first by the dredging process of the cutter suction dredger or the

rake suction dredger.

2.

Solidified contaminant or sludge (can be treated by mechanical

dewatering or geotextile bag consolidation), after dewatering, it can be used

for engineering soil, garden soil, building materials, etc.

3.

Use IDOC indigenous diatom technology to restore the complete ecological

food chain in the river and gradually purify and repair the water body.

Completely solve the river pollution problem and maintain the ecological health

through combination treatment.

Mechanical Dewatering Solution - Dredging, Conditioning and Curing

After the excavated sludge is transported to the shore, it is successively processed by the garbage sorting equipment and the sand water separation equipment to enter the sludge concentrating device. The sludge concentrating device can be treated by gravity concentration tank or stacked screw concentrator according to the project conditions, and the moisture content of the river lake sludge is reduced to below 90%. The sludge which is high organic and difficult to dehydrate can be chemically conditioned. After the sludge is concentrated and conditioned, it is pumped to a special screw press machine for river and lake dredging or a special quick river dredging press to quickly dewater the sludge. The drain water is returned to the water body or the nanotube after being deposit and filter.

△ Multi-Plate Screw Press Machine Special for River and Lake

Dredging:

△The multi plate screw press for river and lake special dredging integrates automatic control cabinet, flocculation and tempering tank, concentrated dewatering body and liquid collecting tank, which can realize high-efficiency flocculation under the condition of fully automatic operation, and continuously complete the concentration and press dewatering work. Finally, the collected filtrate is refluxed or discharged. It has the advantages of high degree of equipment automation, small floor space, low noise, etc. It can also be used for shipboard design.

△ Quick Filter Press Special For River And Lake Dredging:

River and lake dredging projects usually

have tight construction schedules and large processing capacity. Most projects

need to build temporary working platforms near the river. This requires

dewatering equipment to have water-saving and electricity-saving, large

single-machine capacity and simple operation. Based on the standard press,

Techase optimizes the design of these features, which makes the equipment have

the advantages of low water content and large processing capacity, which

greatly improves the processing capacity and effect of the equipment.

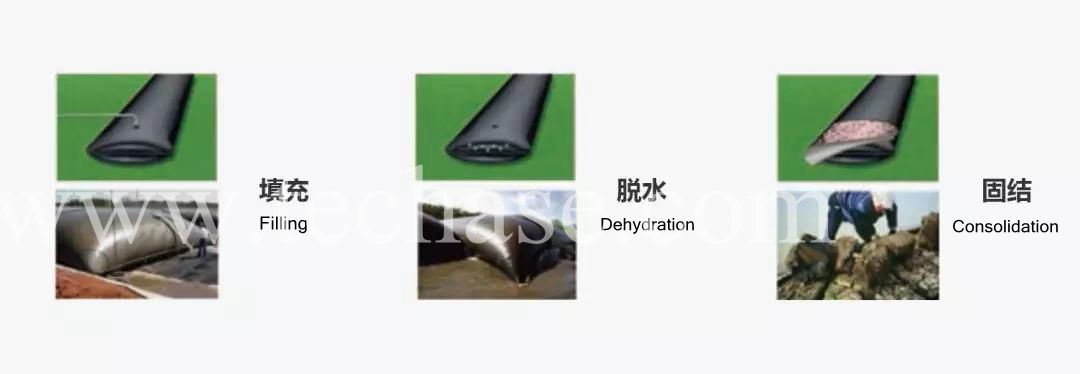

TCGD Consolidation Treatment Plan - Dredging, Conditioning, Curing

The sediment at the bottom of the lake is treated and injected into the geotextile bag. After flocculation and sedimentation, the volume is greatly reduced in a short time. Moreover, the geotextile bag can also be stacked in multiple layers, which greatly reduces the need for land use, and the entire process is completely closed and non-polluting. This process is considered by many people in the industry to be an economical and environmentally friendly treatment for treating riverbed sediments.

△ Geotextile Bag:

The geotextile bag is a tubular geotextile

bag made of polypropylene yarn, and has a filtering structure. It is

characterized by high strength and long-term resistance to ultraviolet rays.

The utility model has the advantages of large processing capacity, simple

installation, small floor space and low cost.

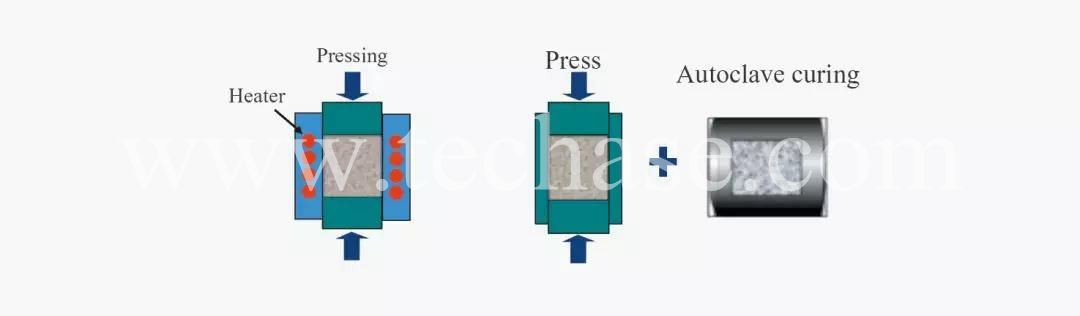

Hydrothermal Brick Making

Hydrothermal compression molding device - a hydrothermal compression device that reacts inorganic waste to a high-strength solidified body at a lower temperature. Due to the pressure and temperature rise of the water hot pressing technology, the curing time is long, the production efficiency is low, and the equipment is relatively complicated, which leads to limit the application and development. Hydrothermal curing technology is a method of separating pressure forming and heat curing to simulate the diagenesis process of the groundwater thermal system. It overcomes the problems of crystal transformation, decomposition and volatilization which are insurmountable in some high-temperature preparations, and has low production cost and uniform particle size of the cured product.

Technical advantages:

1. Through hydrothermal curing technology,

it can process a variety of solid wastes including river sludge, construction waste,

slag, tailings, etc., make them a high value-added brick material, and can also

be repaired in soil to achieve change. Make waste to treasure;

2. Relying on the research platform of the

Materials College of Tongji University, the utilization plan can be customized

according to different wastes. The waste utilization rate can reach up to 80%,

and the chemical properties of the products are stable, will not produce

secondary pollution.