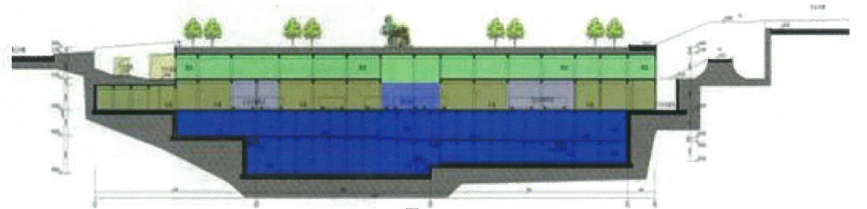

Figure 1

The Pengjiawan area of Guiyang city is the modern business and commerce functional plate of Guihuang road, which is the "city belt of second ring and the four roads". The planning land use is 395.76ha, and the planned population is 474,000. According to the planning requirements, a new wastewater treatment plant should be built in large-scale housing development project of Guiyang to collect and treat the wastewater in the area, so as to reduce the discharge pressure of wastewater intercepting ditch in the Nanming river basin and use the tail water as the landscape used water for the upstream of the river. The comprehensive project in Pengjiawan wulichong shantytown is the first design case combining the underground wastewater plant and the comprehensive project of urban reconstruction in China. It effectively solves the contradiction between wastewater treatment and land demand for urban construction development in old city reconstruction, and minimizes the damage to the ecological environment. The construction form of this project is finally determined to adopt the whole underground type, which is a four-storey underground comprehensive project integrating the ground park, parking lot, shopping mall, bus station and wastewater treatment plant (Figure 1 is the vertical layout of the comprehensive project.). The third and fourth floors underground are wastewater treatment plants with a construction area of 28,406.59 square meters.

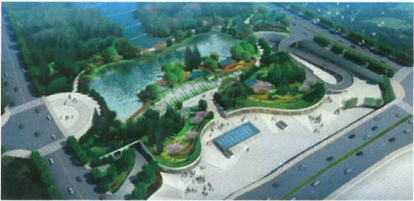

Figure 2

The effect picture of ground landscape is shown in figure 2.

According to the technological process, the wastewater treatment plant sets up pretreatment area, secondary treatment area, deep treatment area, sludge treatment area, public building area, roadway and pipe gallery area. Each area has relative independence and integrity. The total design scale of wastewater treatment is 6.0 104m3/d, the short-term treatment amount is 3.0 10m3/d, and the long-term amount will increase 3.0 104m3/d. The improved A2/0 process is adopted for the biochemical treatment of wastewater. The rectangular weekly inlet and outlet sedimentation tank is adopted for the secondary sedimentation tank. The high efficient sedimentation tank process is adopted for the deep treatment of wastewater, and the ultraviolet disinfection process is adopted for disinfection. Among them, 20% scale of the reclaimed water adopts fiber disc filter and sodium hypochlorite. Sludge thickening and dewatering process adopts our “multi plate screw press and super high pressure filter press”. The moisture content of the sludge outlet is no more than 60%.

With the same capacity, the occupied area of super high pressure filter press is about 30% less than that of the diaphragm press, and the plant height is only 7m. This efficiently uses the underground space and saves valuable land resources. Our super high pressure filter press for municipal sludge and other materials that are difficult to dehydrate can reduce the moisture content of municipal sludge from over 95% to 50% at one time, which solves the problem that organic sludge is difficult to be effectively treated and utilized. This equipment improves the structure of traditional plate and frame, and integrates many advantages such as low investment cost, high dehydration efficiency, small occupied area, good treatment effect and simple operation and maintenance. The super high pressure filter press does not require additional secondary pressure supercharging equipment and press media. It completely relies on spring compression to reduce the volume of the filter chamber. It has large compression ratio, direct force, high pressure and short working cycle. Its production efficiency is 3-4 times of traditional diaphragm filter press.