On the premise of giving full consideration to the operating conditions of the equipment, on-site installation environment and deodorization environment, our company has provided assembling complete sets of treatment equipment for sludge concentration system, sludge modified conditioning system and sludge deep dehydration system.

Main process:

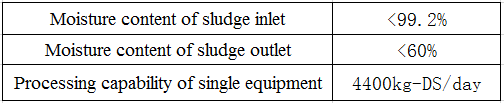

The sludge with moisture content of about

99.2% was transported by screw pump from the sludge tank to the multi plate

screw thickener. The sludge moisture content reached 90%~93%. It was then modified

by polymer dosing, and the treated sludge was compressed and dehydrated to less

than 60% by our super high pressure filter press.

Sludge thickening system

Working principle

Multi plate screw thickening system

includes sludge pump, multi plate screw thickener, full automatic PAM

preparation device, PAM polymer dosing pump, and so on.

Its core equipment is multi plate screw

thickener. It integrates automatic controlling cabinet, flocculation

conditioning tank, sludge thickening body and filtrate collection tank. Sludge

concentration can be completed efficiently and continuously under the condition

of full automatic operation. The collected filtrate will eventually be flowed

back or discharged.

Filtration body

It is composed of fixed rings, moving rings,

screw shaft, gasket and connecting plates. Fixed rings are connected by a

number of screws. The gasket and moving rings are installed between the fixed

rings. The fixed rings and moving rings are made of wear-resistant materials,

which makes the life of the whole machine extended. The screw shaft is inserted

between the fixed rings and moving rings, and the moving rings are hollow on

the screw shaft.

Sludge conditioning system

Working principle

Sludge conditioning system is a general

term for sludge polymer dosing conditioning equipment. It includes PAM

preparation device, PAM dosing pump, FeCl3 solution storage tank and solution

pump, curing agent bin and preparation (storage) of three agents for feeding

screw and dosing equipment. By adding agents to the original sludge, the

physical properties of the sludge can be changed, and the efficiency of sludge

dewatering can be effectively improved.

Mixer

The mixer is installed on the polymer

dosing device. It has unique structure and appropriate speed. Thus the solution

can be homogenized without destroying the polymer chain.

Sludge pressing system

Working principle

The sludge is transported to the super high

pressure filter press by the feeding pump of the press machine after dosing and

adjustment. With the increase of the feeding capacity, pressure is gradually

formed in the chamber of the press, and the sludge is squeezed at the first time.

After a certain period of time, the entire press is filled with sludge. At this

point, we should close the feeding inlet, and the press starts pressing. Super

high pressure filter press can directly act on the filter frame by oil pressure

and squeeze to reduce the volume of the filter chamber to conduct the deep

dewatering of sludge.

Electronic control system

The electronic control system meets the

requirements of equipment operation. Its operation modes are divided into two

modes. The one is local operation, and the other is remote operation. The

control box is responsible for the on-site start, stop and control and overload

protection of the equipment.