After careful plan and preparation work, on

June 3, 2019, Techase brought three protagonists to the Shanghai International

Water Show. The unique design of the booth, the bright visual color, and the

sincere and enthusiastic on-site service, all show the concentration of

Techase.

This time, three protagonists--Multi Plate

Screw Press, YG Type High Pressure Filter press, and continuous conditioning

reactor of Techase debuted grandly, brought everyone the products and solutions

for waste water and sludge treatment.

Three major products

Multi Plate Screw Press

Techase has innovated and reformed on the basis of the traditional stacked screw sludge dewatering machine, and established the theoretical model of ANSYS screw crushing finite element analysis to adjust the screw parameters according to the sludge characteristics to ensure the product operation effect. The fix ring adopts a uniform four-corner loop design to enhance the rigidity of the ring and improve the solid-liquid recovery rate. Facing the special needs of different industries, Techase has launched special machines for petrochemical, sludge, fruit and vegetable, paper and cyanobacteria for different industries. It has been widely used in various industries such as municipal, industrial, food and printing and dyeing.

Product advantages

1. Wide application range, which can

directly concentrate and dehydrate low-concentration sludge, the range can

reach 5000mg/L-50000mg/L;

2. The moving ring replaces the filter

cloth, so that the equipment can self-clean, no clogging, and easy to handle

oily sludge;

3, low speed operation, low energy

consumption, no noise;

4. Reduce the cost of infrastructure

investment and improve the treatment effect;

5, Internet remote control, no manual

guard.

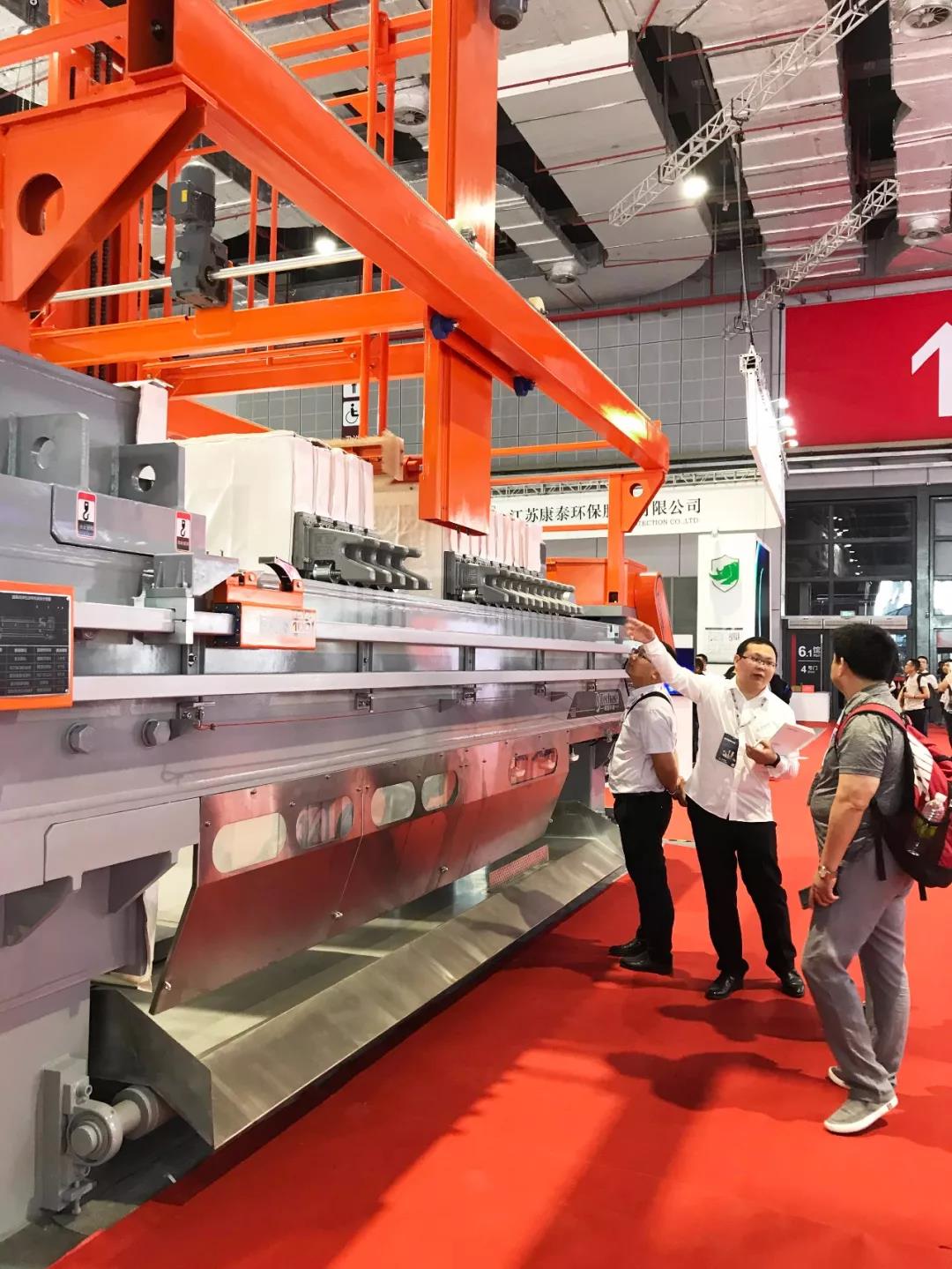

YG Type High Pressure Filter press

YG Type High Pressure Filter press is a high-efficiency pressure filter equipment exclusively developed by Techase, which replaces the press medium spring by small oil cylinder, and the structure is stable and reliable. The compression ratio is adjustable, the feed can be operated at a higher pressure, and the equipment has a long service life and is easy to replace and maintain.

Product Advantages

1. High working efficiency, completely

pressing the elastic medium to squeeze the sludge, the pressing pressure is

2.5~10 MPa;

2. Low energy consumption, low dosage of

chemicals and no secondary pollution, low operating cost;

3, the work cycle is short, the processing

capacity is large, which is 3~4 times of the traditional plate and frame filter

press;

4, metal filter frame and elastic medium,

durable (can be used for more than 8 years), only need to change the filter

cloth

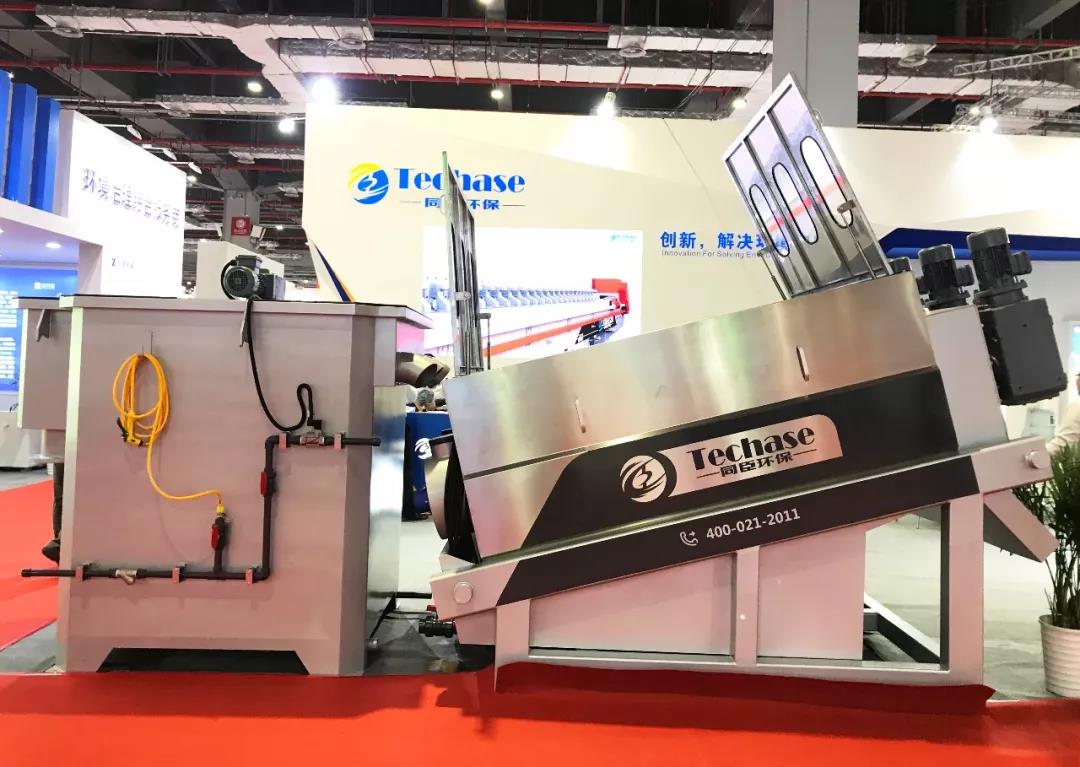

Continuous Conditioning Reactor

The continuous conditioning reactor can monitor the nature and curve of the incoming mud in real time, and adjust the dosage method and dosage volume, and can independently adjust the reaction time of the agent and the stirring mode according to the nature of the agent in each segment to improve the conditioning efficiency.

Product Advantages

1. Product standardization design, complete

functions, simple operation and management;

2, Fully automated, small footprint,

reducing plant area by 15%;

3, Use liquid conditioning agent to avoid

the addition of lime and other powder, Operation environment is well;

4. High applicability, suitable for all

deep dewatering equipment.

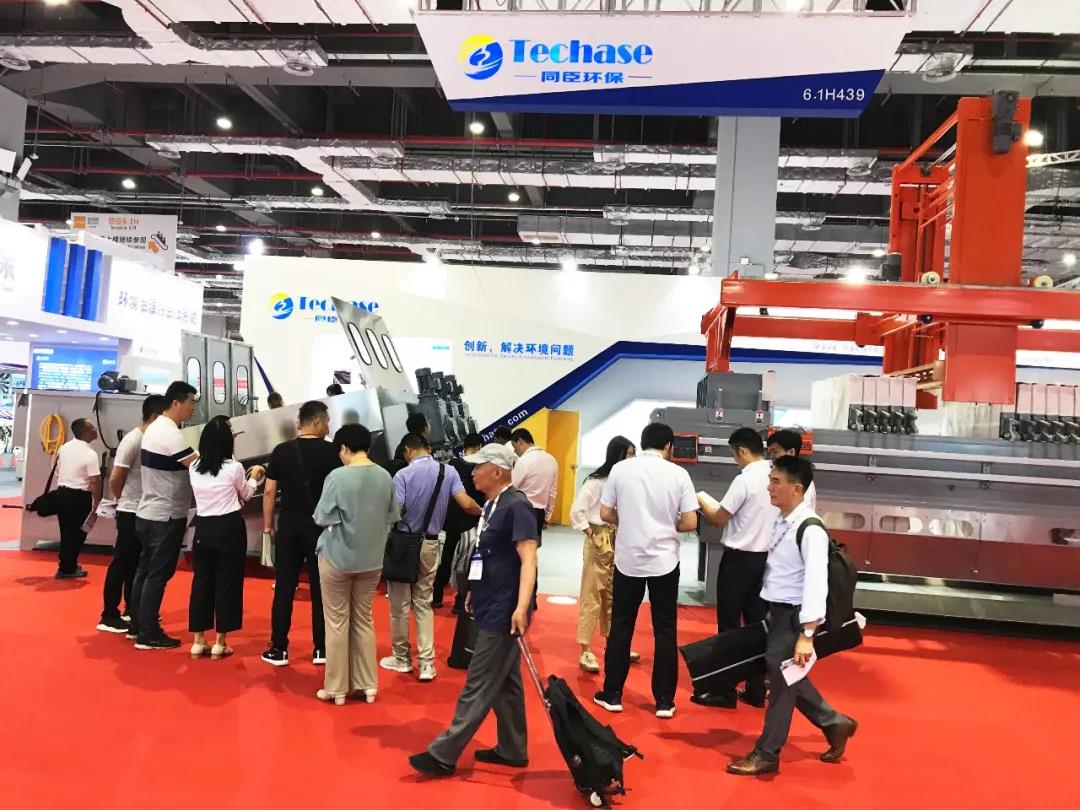

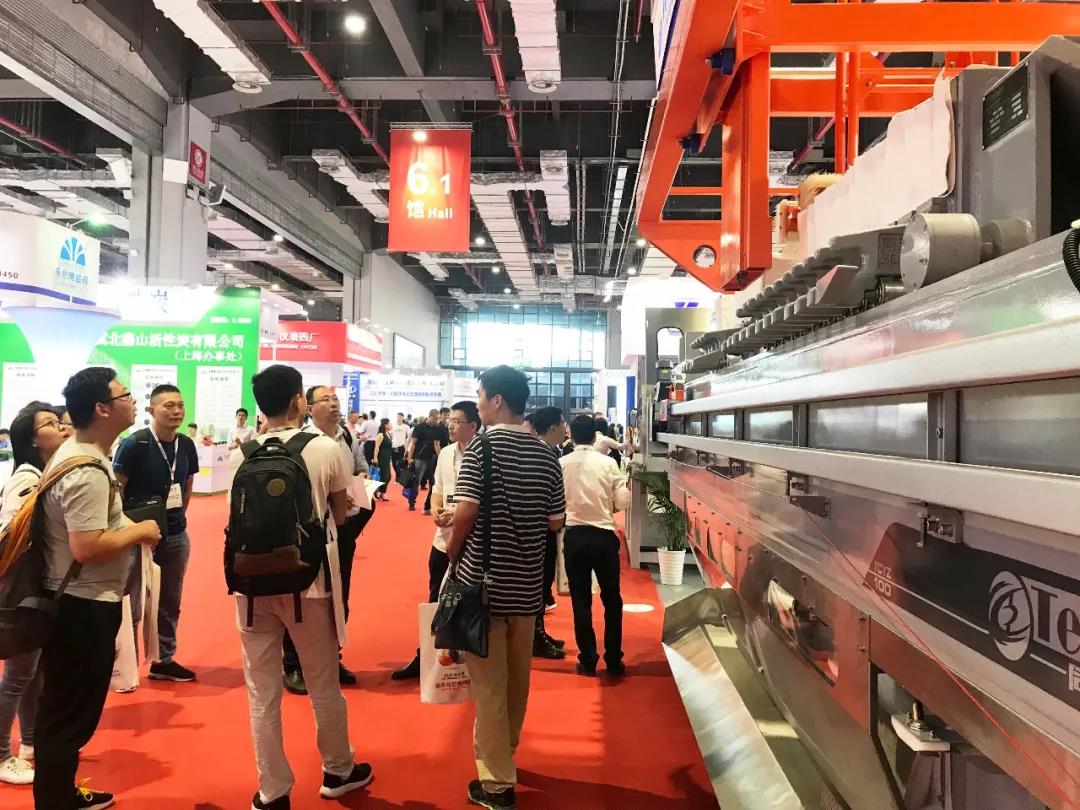

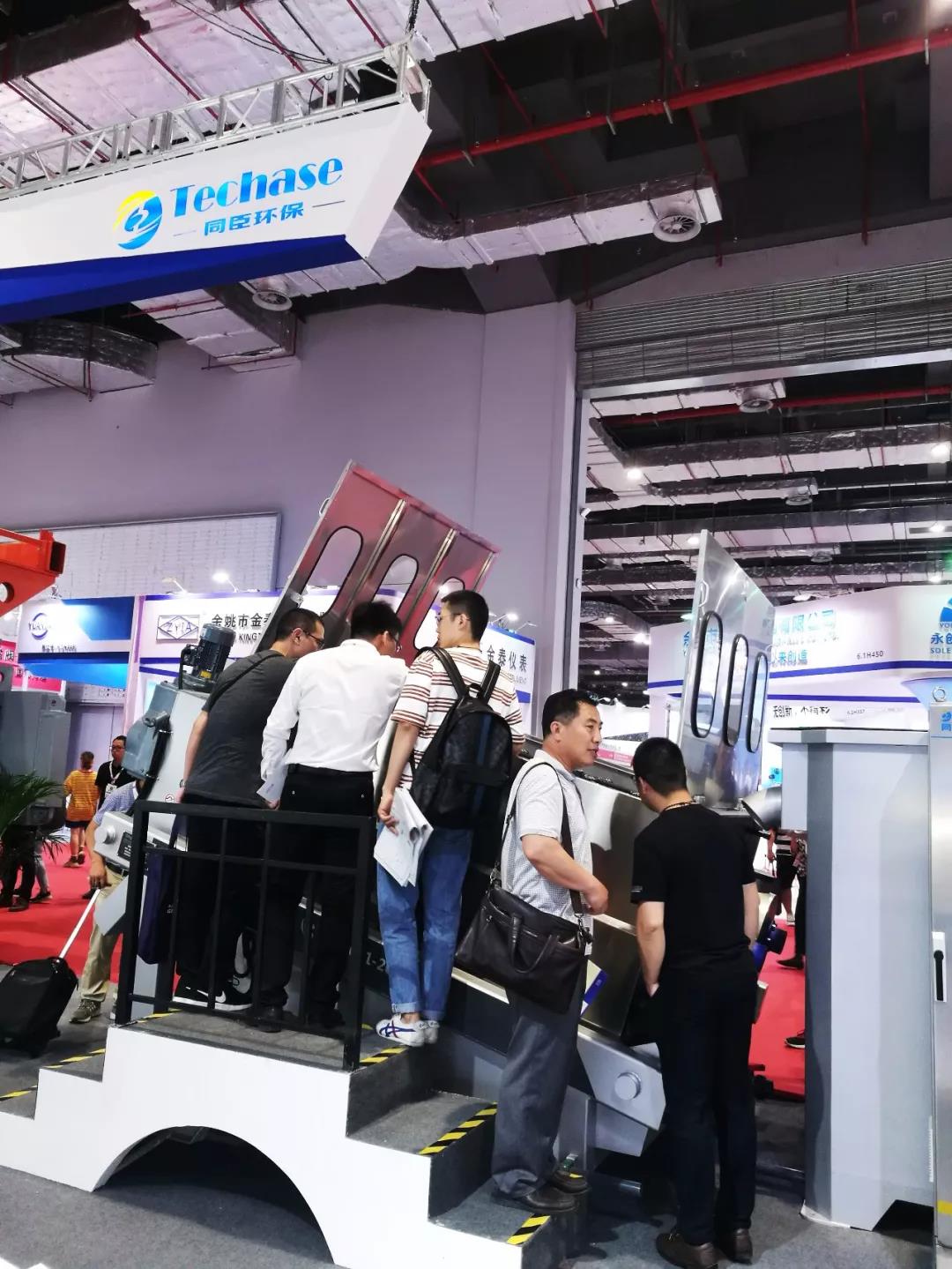

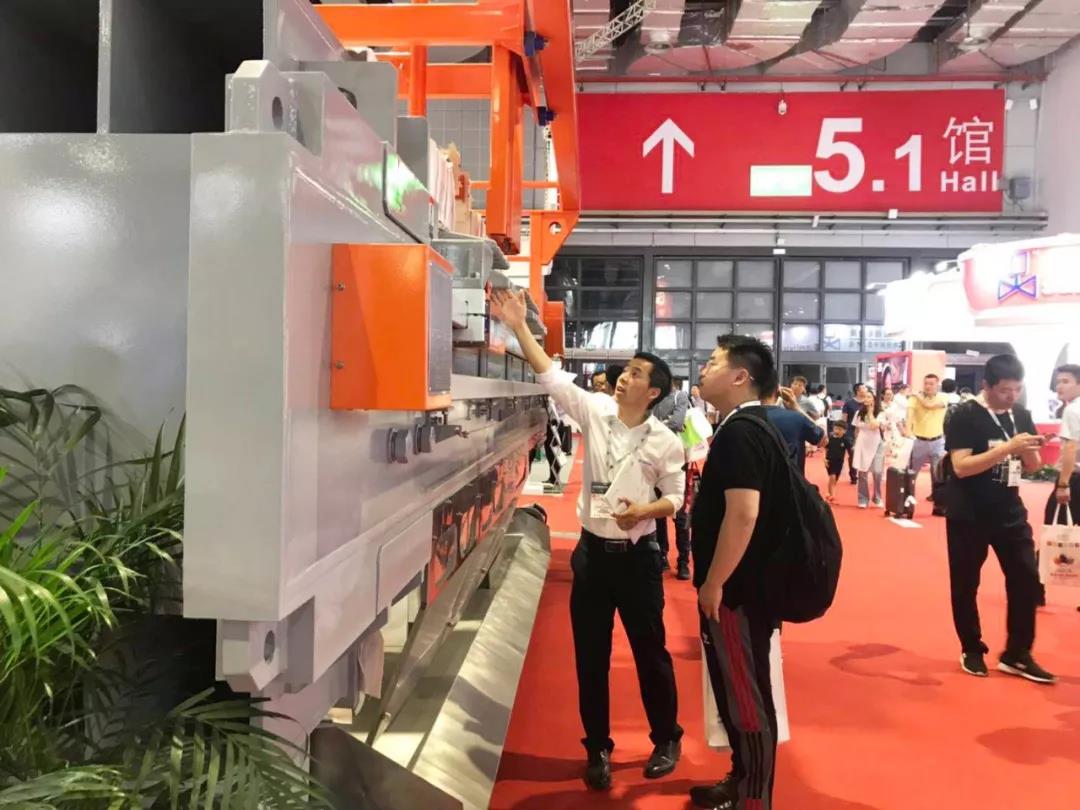

Exhibition Glimpse

Display Area

In Hall 6.1, Techase booth was warmed with visits, attracted a large number of people to stop. Every sales of Techase was passionate and sincere to answer each visitors and clients.

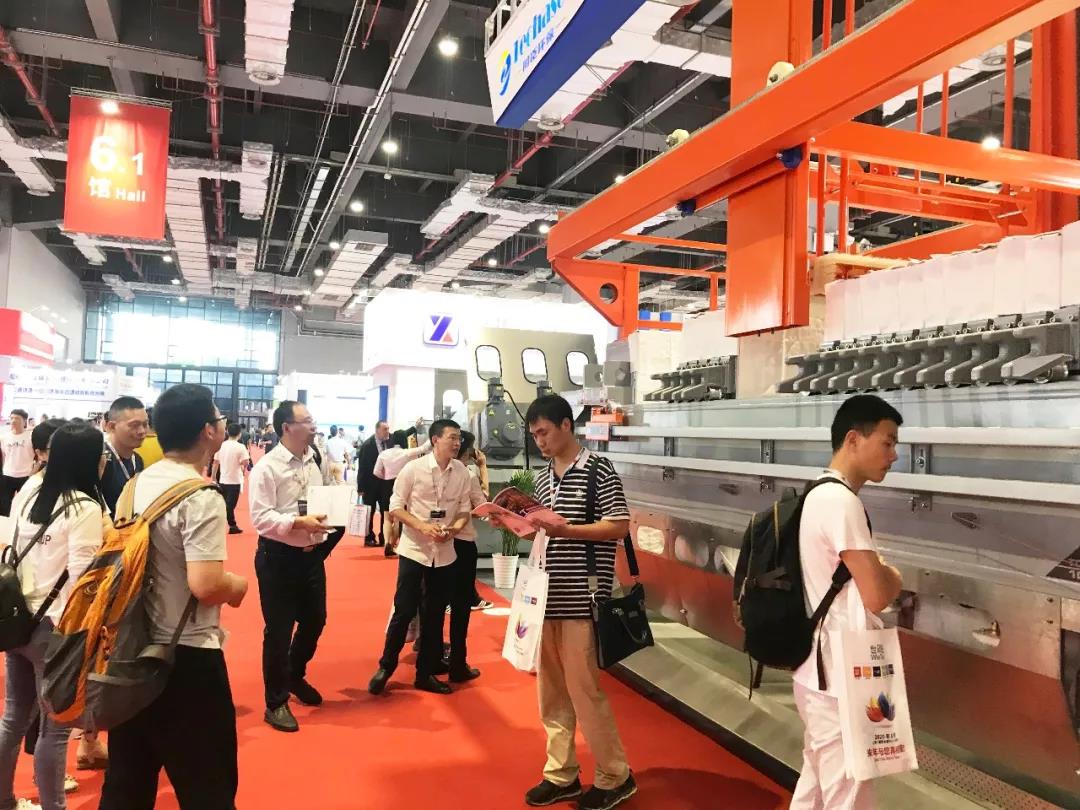

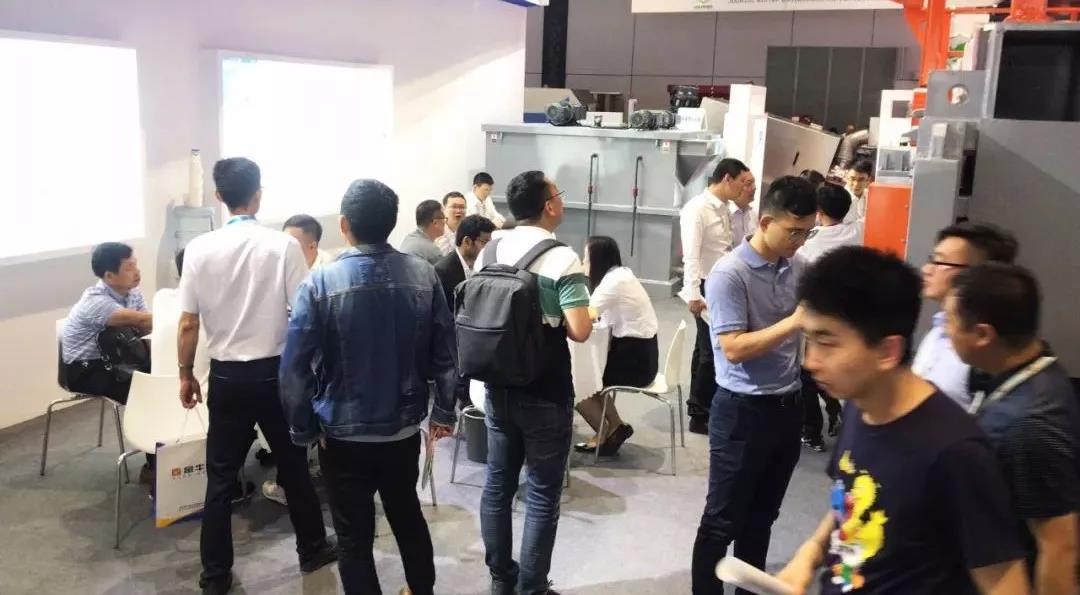

Chat Area

In the rest negotiation area, the sales staff was giving detailed explanations to the domestic and foreign customers.

Live Footage

Products with ingenuity and sincere service

Just to provide you the perfect customer

experience