In the sludge dewatering industry, as an old brand of environmental protection equipment with ten years of experience, we focus on the innovation and R&D of products. The multi plate screw press produced by us has become the first brand in the dewatering industry and the leader in the development of the industry.

And in the development of this 10 years, the user cases of our screw press are the most. It had already became the first selection of numerous users. What's the ace in the hole?

Strong ability of cleaning and environmental protection

Through technological innovation and R&D, the equipment itself has the advantages of self-cleaning and non-clogging. Compared with the traditional dewatering machine, it has stronger processing capacity and better performance. The specific performance is the following two points.

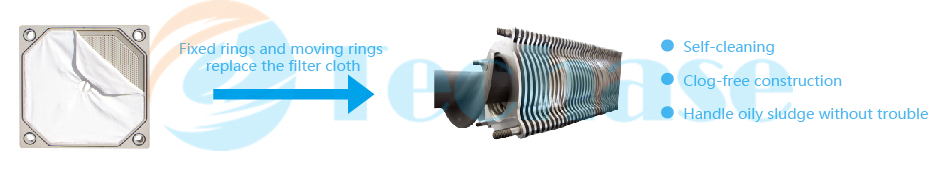

1. Fixed and moving rings replace filter cloth, self-cleaning, clog-free, easy to handle oily sludge

The traditional dewatering equipment are easily got blocked while the multi plate screw press allows continuous operation with no blocking due to that the moving of the fixed rings and moving rings cleans itself. Therefore, it’s especially good at the oily sludge with excellent performance. Moreover, it doesn’t need additional water for high-pressure cleaning so that no smell or secondary pollution will be produced.

2. A wide solid concentration ranging from 5000mg/l to 50000mg/l

The thickening zone and the dewatering zone make the machine applicable to both highly concentrated sludge and that with a high water content. It’s able to directly treat sludge with a solid content from 5000mg/l to 50000mg/l.

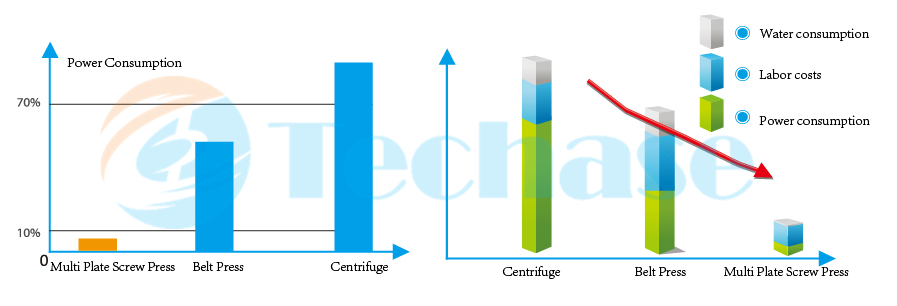

Low power consumption

In the purchase of equipment, the operating energy consumption of equipment is also the focus of many customers. High power consumption will directly increase the operating cost. For this point, our screw press has a great advantage.

The dewatering of our multi plate screw press relies on the inner pressure of the filter chamber and the rotating speed is as slow as 2~4r/min. Therefore, its power consumption is as low as 0.01~0.1 kw/h/kg-DS, only 1/8 of that of belt presses and 1/20 of that of centrifugal machines. In addition, of course there is little noise. Eventually, the operating cost can be greatly saved.

Less investment cost, more excellent working performance

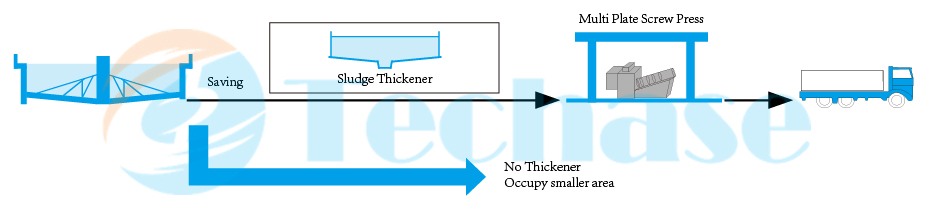

When working on a project, many people will consider whether there are many supporting facilities for the main equipment. Does it cover a large area? These factors directly affect the implementation of the whole project, and we fundamentally solve these problems through technical R&D.

The multi plate screw press can directly treat the sludge from the aeration tank and the secondary sedimentation tank so that the sludge thickening tank is not needed any longer. Therefore, the capital construction cost can be greatly saved and the phosphorus releasing problem is well avoided.

1. Save construction investment on sludge thickeners and costs on mixers, air compressors, flushing pumps, and other auxiliary equipment.

2. Occupy smaller area, reduce construction investment for dewatering room.

Unique core component

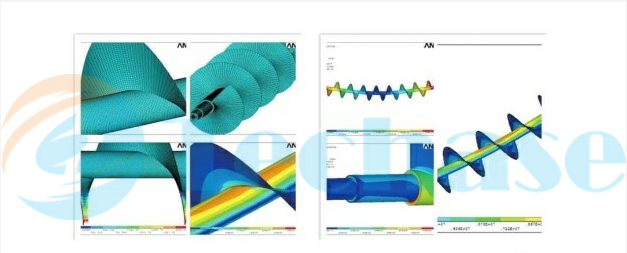

As the core component of the screw press, the screw shaft affects the operation of the whole equipment to a great extent. After years of research and integration of various technologies, we have made a new technical reform of the screw shaft. Specific performance is the following three points.

1. ANSYS model analysis

We adjust screw shafts parameters according to sludge characteristics to ensure the operation effect of products, and launch the special shafts for different industry according to different industry characteristics (petrochemical, fruit and vegetable, paper industry, river and lake, sludge concentration, amyloid industry, blue algae, etc.).

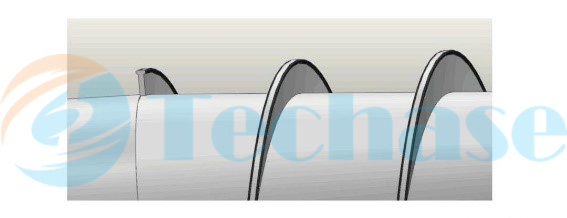

2. It is 150 times the thickness of the super wear resistant carbide material. The length of the screw shaft is extended by 15%.

The screw shaft adopts a process of surfacing super wear resistant carbide material. The thickness of alloy layer is increased 150 times, and the length of screw shaft is increased by 15%.

3. Super wear resistant carbide material

It is widely used in the manufacture of cutting tools, wear-resisting parts, kiln structural materials, jet engine parts, metal-ceramic materials, resistance heating elements and so on.

Wear-resistant, easy to operate

With the professional skills and the spirit of continuous improvement, innovation and R&D, we use modern high-tech technology to make the operation of equipment convenient and simple. Specific performance is the following three points.

1. IOT remote control system

Unique IOT remote control system is easy to operate. It also can be set to 24-hour unattended automatic operation via the electric control cabinet.

2. Frequency conversion motor driving system can be controlled independently.

It adopts independent frequency conversion motor driving system with smooth startup, which can be started or stopped separately.

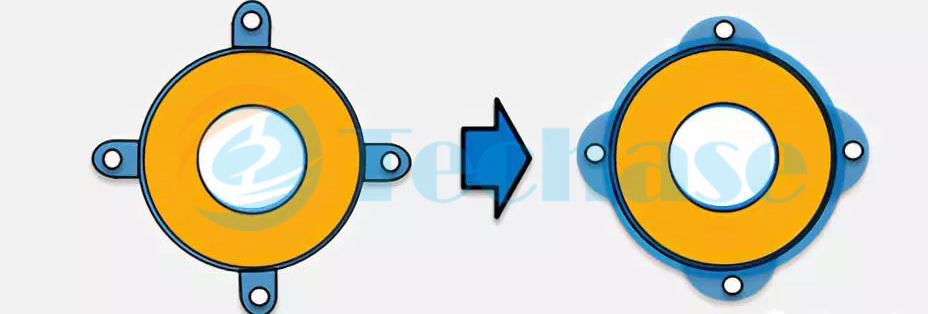

3. The fixed ring is designed with quadrangle curved ring.

The fixed ring of the screw press is designed with uniform quadrangle curved ring, which enhances the rigidity of the fixed ring and makes the equipment more wear-resistant.

In this decade, with these aces in the hole, our screw press has been exported to more than 80 countries and regions. It is well received by the majority of customers. Of course, we will not stop here. With the rapid development of environmental protection technology at present, we should take the strengths of others to make up for our weaknesses with continuous innovation and progress in order to operate permanently in the highly competitive environmental protection market!