Without proper operation and maintenance,

the service life of Multi Plate Screw Press (Hereinafter referred to as MSP)

will be reduced in the long run. Therefore, it’s significant for end users to

maintain and operate the machine in a right way, which can not only maintain good

performance, but also improve the working efficiency and reduce economic

losses.

Key Points: Improper Operation + Daily

Check + Maintenance + Trouble Shooting

Improper Operation Causes High Failure Rate

Situation 1: Unscheduled Maintenance

According to statistics, 85% failure rate

of MSP is caused by unscheduled or improperly maintenance. The key point to

prolong the service life of MSP and improve the working efficiency is to do

scheduled maintenance.

Situation 2: Overload Input Sludge

When the sludge inflow exceeds the

capacity, the pressure in the main body is so large that the friction between

moving rings and fixed rings will increase, which is easy for them to be

abraded. Therefore, it is necessary to adjust the sludge inflow according to the

handling capacity to avoid overload operation.

Situation 3: No Maintenance Before Long

Downtime

If you don’t clean MSP before long

downtime, the residual sludge between the moving rings and fixed rings get dry

and hard, which may block and stuck the rings. Keep multi plate screw press

running for half an hour before stop it. If necessary, adjust the back pressure

plate to the maximum gap and let sludge inside to be completely drained. Then

clean the machine.

Situation 4: Hard Objects Enter Into Dewatering

Body

When big slag blocks and other hard objects

enter the dewatering body, the fixed rings and moving rings may be stuck to

make the machine out of order. To avoid the situation, you can add a filter at

the inlet to filtrate large volume hard objects.

Daily Check Guarantees High Efficiency

To maintain high efficiency, great quality,

low cost and continuous operaion, the operators should do the daily inspection

and maintenance to prolong its service life and improve the working efficiency.

Equipment Inspection

Equipment inspection is an effective means

to correctly and timely grasp the technical status of the equipment and carry

out equipment condition monitoring and maintenance. It is an important work to

ensure the normal operation by checking the machine, you can discover and

eliminate hazards to prevent the sudden failure and accident.

1.Daily Inspection

The daily Inspection is that the operators

carry out a comprehensive technical inspection of all parts of the equipment

according to the prescribed standards.

2.Key Inspection

The operators check and record the key

parts each shift or at a certain time according to the equipment spot check

card. Maintenance crews do effective maintenance and elimination according to

the spot check card.

3.Regular Inspection

The maintenance screws should conduct a

comprehensive inspection and measurement of the equipment performance to look

for some problems. Besides debugging, they will also make detailed records of

the inspection results as the basis of the equipment maintenance plan.

As for daily maintenance of MSP, cleanness,

tidiness, lubrication, fastening, adjustment, corrosion prevention and safety

should be as the daily maintenance items to check. In addition, establishing an

effective maintenance management system to standardize and supervise for MSP is

also necessary.

Maintenance Management

In order to improve the standard of the

equipment maintenance management and build comprehensive management system, normalization,

technologization, institutionalization should be achieved during the

maintenance.

1.Normalization

Normalization is the maintenance of content

unity. For example, Formulate relevant process regulations to normalize which

parts of MSP should be adjusted and which devices should be checked, etc.

2.Technologization

Technologization is to specify the process

of maintenance management according to the applications of MSP in different

crafts, and maintain the system according to relevant process regulations.

3.Institutionalization

Institutionalization, which is based on the

different working conditions of MSP, is to specify different maintenance cycles

and time rules and operators should strictly carry out it.

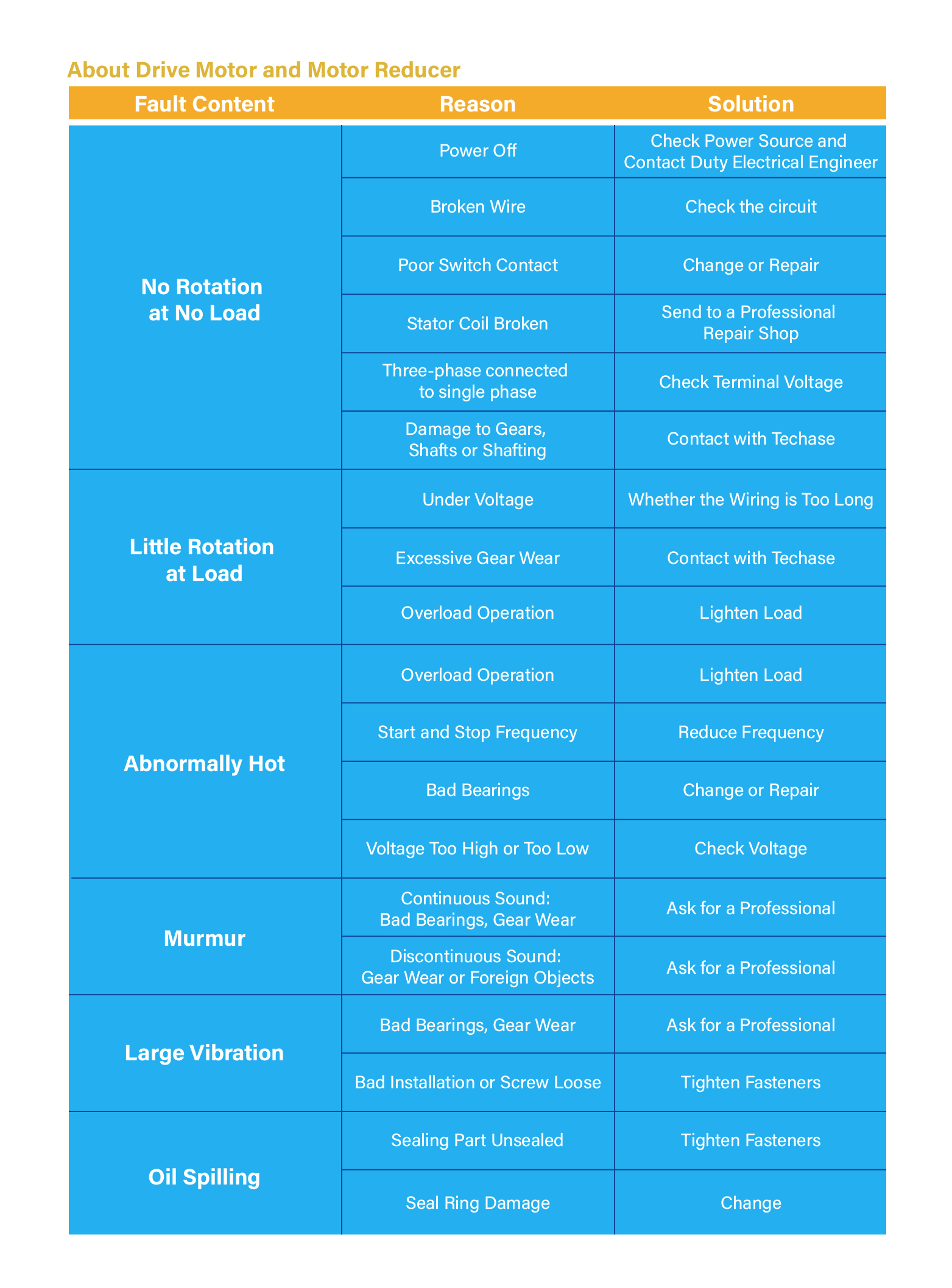

Trouble Shooting

Equipment Debugging Emergency Fault Analysis

& Solutions

1. When cleaning the site manually, the

workers accidentally sprinkle water on the motor, electric cabinet and other

electrical components: Turn off the power and dewater the motor.

2.Accidentally drop tools or other things

into the mixing tank: Turn off the mixing machine, empty the sludge from the

mixing tank, and take out the corresponding material.

3. Accidentally drop the tools and plastic

pipes at the sludge entrance of MSP: Turn off the dewatering motor, open the

bellows behind the dewatering machine, adjust the direction of rotation of the

dewatering motor, turn on the motor, wait until you see something back, turn

off the dewatering motor and take out the things that fall in.

4.In the operation of back pressure plate

clearance adjustment, drop tools into the screw conveyor: Turn off the screw

conveyor, open the cover plate on the screw shaft and take out the tools.

5.When operating the dosing system, sludge

pump and mixing tank, accidentally encounter splashing liquid: Use different

cleaning methods according to different liquids.

6.During the debugging, a power failure

occurred suddenly and the equipment is not emptied: Turn off the control switch

on MSP, clean and empty the machine after power supply.

7.During the debugging, due to the problems

of dosage or sludge intake, the sludge cake discharged from the sludge outlet

has a high moisture content or contains a large amount of liquid into the screw

conveying system: Stop screw motors, sludge feeding pumps and MSP.

8.During the debugging, the sludge cake

storage tank has been filled with sludge cake: Stop MSP system.