Yunmeng belongs to Xiaogan, Hubei, which is

located in the east of central Hubei and the north east of Jianghan Plain.

Yunmeng has a long history of more than 1400 years, established in Western Wei

Dynasty. It’s famous for its water, and was chanted by literati. Yunshui

National Wetland Park is here. Besides, there are 9 rivers in it, including two

water systems (Fu River and Hanbei River). In the early days of the nation, the

27 rivers covers an area of 27685 mu of land.

Yunmeng Donghai Water Supplies Co., Ltd.

plans to treat 50000 tons of water per day and the main source of sewage is

urban domestic sewage. It adopted 2 centrifugal sludge dewatering equipment

before, which could lower the moisture content of sludge to less than 80%. However,

in recent years, the policies for sludge treatment requirements are improving, the

moisture content must be reduced to 60%. Therefore, it is urgent to upgrade the

dewatering machine room. According to the requirements, Techase provided a full

set of sludge advanced dewatering technology, filter press machine also existed

in this system.

1.Great Effect of Treatment

The moisture content of final output sludge

cake is less than 58%

High Strength, Good Breathability

No Secondary Sludge

Sludge Reduction of 50%, Treatment Freight Reduced

by a Half

2.Excellent Treatment Capacity

Working Cycle: Short

Handling Capacity: Up to 5-8kg/ (㎡﹒h)

3.Low Operation Cost

Steel Frame: Hard to be Damaged

Service Life: Longer than Traditional Equipment

(8 years)

Others: High Intelligence, Simple Operation

and Low Cost

4.High Integration

Compact Structure

Less Footprint (Nearly 50%)

Reduce Civil Engineering Construction Cost

5.Tidy On-site Environment

Quiet Operation

Clean Operation

No Secondary Pollution

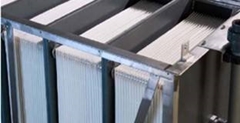

TCYZ-100-TH Series Super-high Pressure

Filter Press

Processing Time (Per batch):100min (Less

time than traditional equipment by 20%)

Working Time (Per day): 12h

Working Batch (Per day): 7 batch

Dry Solids Capacity (Per batch): 0.75tDS

(More production than traditional equipment by 50%)

Operation Control Mode: PLC Automatic Control

TECN-402 Series Multi Plate Screw Thickener

Handling Capacity: 360-600kg-DS/h

Moisture Content of Sludge: 90-93% (Adjust

freely in the range of 90%-96%, stable moisture content, high handling

efficiency)

TCZB-3000 Series PAM Automatic Polymer

Station

Scale: 3m³

Control Mode: Automatic

Techase will continue to be rooted in the

sludge and sewage treatment area to improve the technical level, solve the new

problems and do our best for environmental protection career.