As one of the core equipment in the field

of waste water and sludge treatment, filter press has been highly anticipated

and valued in the industry. In 2013, Techase launched the super high pressure

filter press. Its annual market turnover are always ranked first in the

company's products, and it is the star product of our company.

The

continuous increase in sales performance and the continuous expansion of market

share have provided solid barriers and guarantees for the super high pressure

filter press. Of course, it can be debuted and popular up to now, besides its

own strength, the focus and persistence that Techase has devoted to also is the

reason. In addition to the nice appearance design, what else does it have?

High

Efficiency, Good Pressing Performance

When

choosing a filter press, the efficiency and performance is the core. Treatment

capacity and pressing performance are the priorities for consideration.

After

many years of study and technological innovation, combination with traditional

technology, Techase has introduced three series of super high pressure presses

which are KS series, TH series and YG series. The pressing pressure is as high

as 2.5-10Mpa that unit working period is much shorter. And for using parallel

extrusion, the moisture content of the sludge cake is uniform and below

60%~50%.

Steel

Material, More Reliable

As the

saying goes: a handy tool makes a handyman. Material determines the service

life and performance of the product to a large extent because quality is the

life of the product.

Through

completely research and exploration, Techase has made innovations in the

material structure of the super High Pressure filter press that we use filter

plates of steel material. This makes filter plates much more durable and

service life even can achieve about 5~8 years, which effectively reduces the

replacement maintenance costs of the filter plate.

Low

Operating Cost, Less Investment

When

the equipment is put into operation on site, the maintenance cost of the spare

parts associated with it is also highly valued. Sometimes the cost is too high

or the maintenance is inconvenient, which will affect the operation of the

equipment and even the progress and effect of the entire project.

After

completely understanding and technical reform, the super high pressure filter press

independently developed by Techase has the advantages of low energy consumption

and low operating cost. The equipment has less wearing parts and it only needs

to replace the filter cloth, which greatly saves the investment and operating

costs of the equipment.

Outstanding

Appearance Design, Friendly Operating Environment

Super

high pressure filter press is not only outstanding in appearance design, but

also friendly for site operation environment which makes daily work much

convenient.

While

pursuing high efficiency of equipment, Techase also pays more attention to the

operating environment of the equipment and strives to establish a good

workspace for customers. Moreover, for product design, the equipment is of high

level of automation, simple and convenient operation, and excellent on-site

environment.

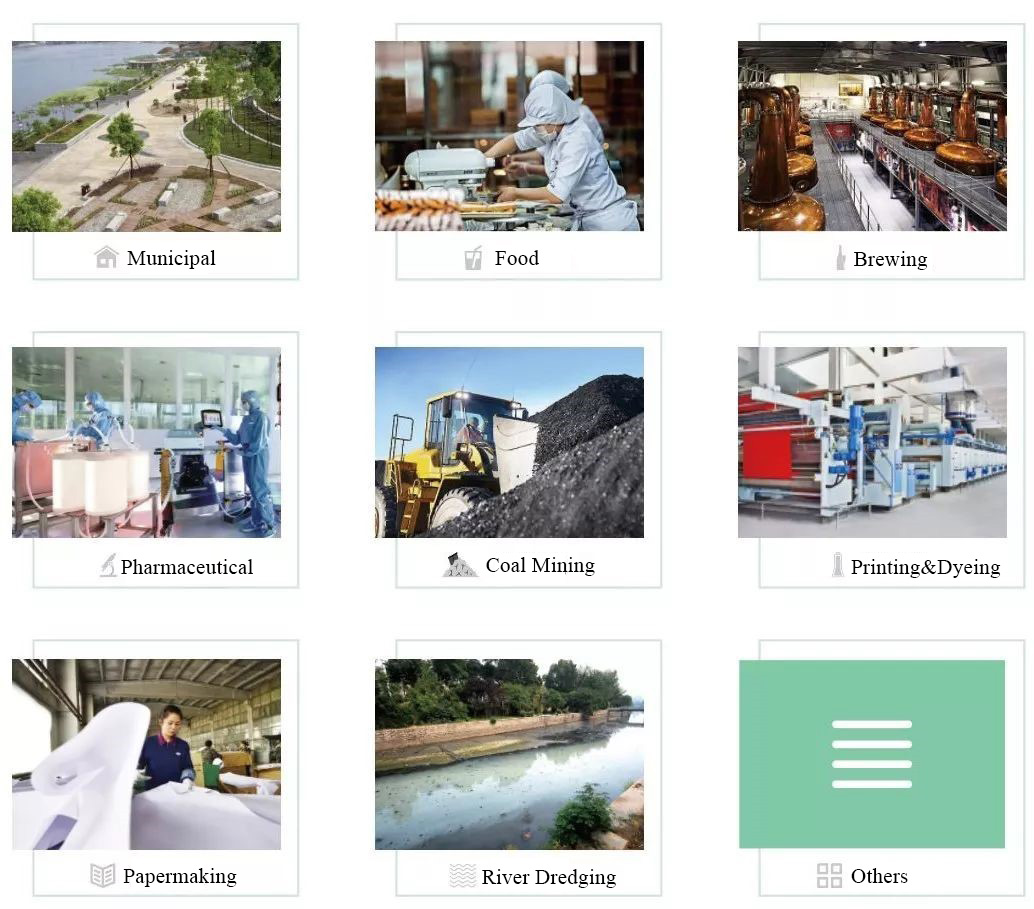

Wide

Options Available for Industries & Applications

The

super high pressure filter press produced by Techase can not only solve the

environmental problems on-site, but also cover a wide range of applications to

meet variety of industry demands.

Up to

now, super high pressure filter press produced by Techase have been widely used

in municipal, food, brewing, pharmaceutical, coal mining, printing and dyeing,

papermaking, river dredging and other industries. The project effect are stable

and received high praise from customers.