Qingdao Chongjie Environmental Protection Pingdu City Sewage Treatment Co., Ltd. was established in May 2003. The company is located in the south of Pingdu City, on the north bank of Zehe River and covers an area of 80 mu. With the BOT operation model, its franchise operation period is 20 years, and the treated water quality meets the first class A standard specified in the national standard GB18918-2002 of Pollutant discharge standards of urban wastewater treatment plants. The project was completed in three phases. As the phase III expansion of the wastewater treatment of the 12th five year key energy-saving and emission reduction projects in Pingdu City, it uses vertical fiber cloth media filter for deep filtration, and the discharged wastewater needs to reach the national first class A standard. At present, the company's comprehensive designed treatment capacity is 110,000 tons/day, the coefficient of variation is 1.4, and the maximum impact resistance is 154,000 tons/day. All the domestic and industrial wastewater in the urban area of Pingdu City can be completely disposed of, with a treatment rate of 100%. The entire system is highly reliable and the water output is stable to the standard. It is expected that the entire wastewater treatment work in the planning area of Pingdu City can be completely resolved within at least 5 years.

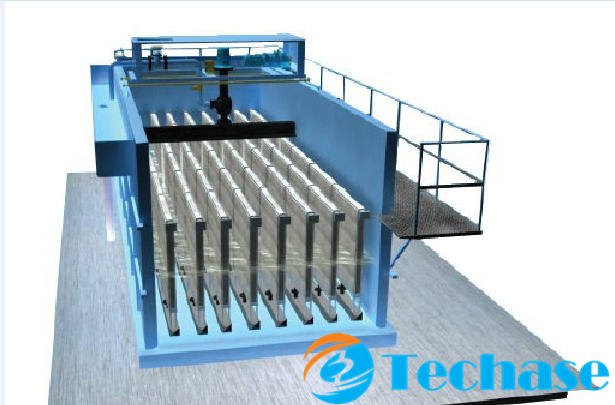

Vertical Fiber Cloth Media Filter

TECF vertical fiber cloth media filter was exclusively designed and manufactured by Shanghai Techase Environment Protection Co., Ltd., in cooperating with Tonggi University. The filter was honored “11th five year national science and technology promotion product” and has many advantages compared with the traditional filters, including low energy consumption, high filtration speed, high capacity, good effluent quality, small space, low operating cost and applicable for different types of wastewater. When combined with coagulation process, the filter can reduce the SS content, thus upgrade the effluent from the first class B to the first class A standard, which in turn upgrade the wastewater treatment plant.

Working Principle:

The Vertical Fiber Cloth Media Filter

mainly consists of a tank, filter packs, travelling backwash crane, tubes and

influent & effluent channels. Each piece of filter pack is a standard-sized

square frame covered with fiber cloths. The travelling backwash system is

driven by a motor and works without stopping filtration. The filtration system

generally includes 2 processes:

Filtration - The water goes into the filter

through the inlet pipes and enters into the filter frames by passing through

the fiber clothes due to the gravity and pressure. Then the filtered water

flows out from the outlet pipes equipped on the bottom.

Backwash - Along with the filtering process, more and more suspended solids deposits on the surface of the fiber clothes, for which the filtering speed gradually slows down. Therefore, the water level gradually rises. When the water level rises to a specific height, the travelling crane automatically starts working and drives the suction tubes to absorb the suspended solids on the surface of the fiber cloth. Then the fiber clothes are cleaned. The dirty water with suspended solids will be discharged by a pump.