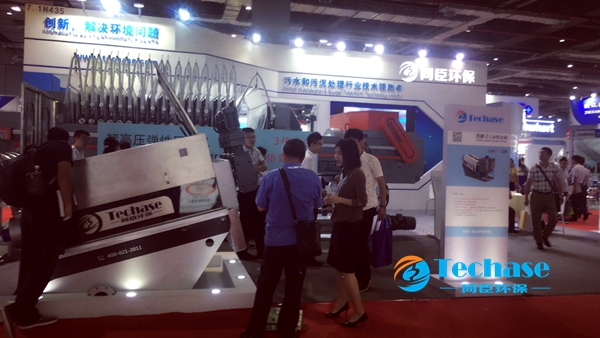

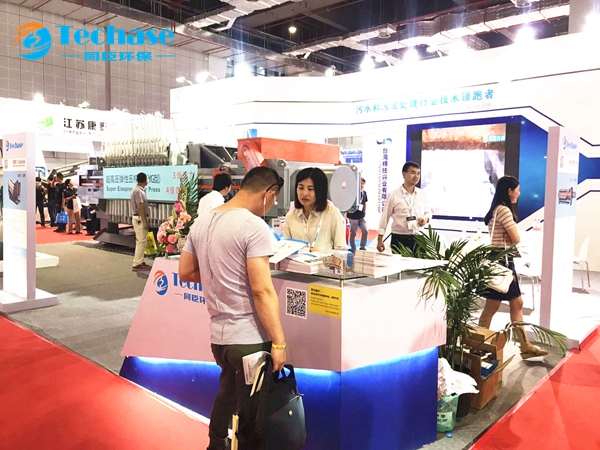

On June 7, 2017, 2017 AQUATECH CHINA Shanghai International Water Exhibition was grandly held in the National Convention and Exhibition Center (Shanghai). The leader of the sludge treatment industry TECHASE showed in the fair with our “secret weapon”.

Techase Multi Plate Screw Press (TECH Series)

As the core product of TECHASE, Techase Multi Plate Screw Press revolutionarily use rings made of CFRP which are more of wear resistance, corrosion resistance, anti-aging, high mechanical strength. The revolutionary ring shape makes the performance more stable. The screw shaft adopts the industry-leading surfacing process, and the processing of more than 40 processes makes the shaft better and more wearable. Sludge scraper design ensures that the sludge discharge port has no block and become smoother.

Techase Multi Plate Screw Press has been actively involved in various industries, including the fruit and vegetable processing, sludge dewatering, pharmaceutical, and aquaculture and so on. Techase launched the industry dedicated machine to meet the special needs of relevant industry users by analyzing industry characteristics, combing with Techase's technological innovation advantages, and constantly tailor for the industry users targeted industry-specific solutions.

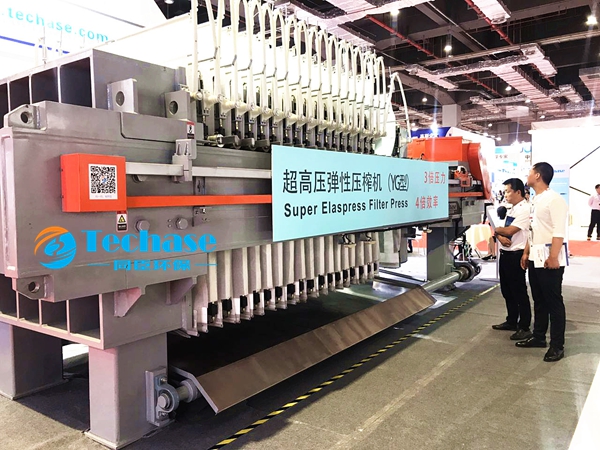

Super High Pressure Filter Press (YG Series)

Super High Pressure Filter Press (YG Series), is a deformation of the original TCZB Series Super High Pressure Filter Press. This new technology uses small cylinders instead of steel springs to provide a higher compression ratio so that the moisture content of mud cake is greatly reduced.

The working principle of the small cylinder overcomes the ultimate compression state of the chamber due to the characteristics of the spring itself, and is well designed to better form the mud cake and squeeze the moisture in the mud cake while overcoming the disadvantages of the steel springs.

The small cylinder can provide a steady pressure to ensure the frame surface seal pressure while sludge is being pumped into the filter press. The amount of mud is further increased. TECHASE spring type filter presss research continues to advance, so that filter presss run more stable, longer life of the various components.

Features:

1. Small cylinder replacing steel spring makes the structure more stable and reliable.

2. Compression ratio can be adjusted.

3. The sludge can be fed at higher pressure without spraying

4. Elastic media has longer service life, easier to maintain and replace.

Comprehensive treatment of black and black water

1, mechanical dehydration program

Silt transport ashore - garbage sorting, sand and water separation - sludge concentration - chemical conditioning (for organic matter content is high, difficult to dewatering sludge) - sludge dewatering (river and lake dredging special stacking machine or river lake dredging Fast filter press). The filter process returns the tail water by the static to the water or tube.

2, TCGD consolidation treatment program - dredging, conditioning, curing

After the treatment of the sediment into the soil bag, the flocculation sedimentation, drain water filtration significantly reduced volume. Through the multi-layer stacking of soil pipe bag, reduce the demand for land. The process is completely closed and pollution-free, is a cheap and environmentally friendly rivers and lakes pollution sediment treatment.

3, IDOC indigenous diatoms directional amplification of water ecological restoration

Aiming at the pollution of the urban river channel as well as the elimination of black smelly and ecological reconstruction, we propose a new technology to realize river dike of high efficiency and low consumption through the construction of the complete food chain by orienting the indigenous diatoms in the edible target water. Bio - remediation technology for directional expansion of indigenous diatoms.