1. Project location

The project is located in Thirty Mile Fortress Industrial Zone which is near the port, Puwan New District, Dalian City. The waste water treatment plant covers a total area of 7.01 hectares. The first phase covers a total area of 1.7759 hectares.

2. Natural conditions

Puwan new district is a warm temperate monsoon climate. It has the characteristics of ocean climate. The climate is mild and humid. Due to the influence of the East Asian monsoon, the climate is distinct in the four seasons, the winter is longer, followed by summer, and the transition season of spring and autumn is the shortest.

3. Project scale

The main service scope is Thirty Mile Fortress Industrial Zone which is near the port and its southern area. It treats pre-treated waste water and domestic sewage.

4. Treatment process

The project plans to adopt the “modified A2/O and microflocculation filtration” process. The effluent is disinfected by ultraviolet light.

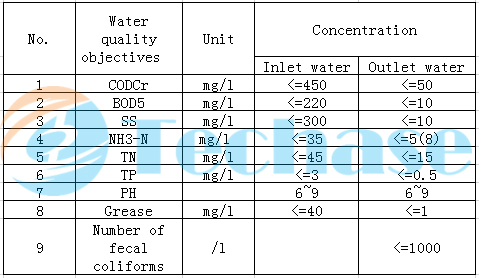

5. Design of water quality of the inlet and outlet water

6. Overall performance requirements

a. The treatment process of sludge concentration dehydration is not limited. Process debugging must meet two criteria. The first is that the moisture content of the sludge after dehydration is not more than 60%. The second is that the total proportion of treatment chemicals in the dry sludge is not more than 25%.

b. The system produces 4 to 5 tons of dry sludge per day. The working cycle of the sludge dehydration system is designed to be no more than 15 hours per day. There are two screw press machines (one for use and one for standby). The operation requires automatic control of the whole process.

7. Main equipment configuration requirements

a. The selected equipment must take full consideration of corrosion and wear resistance. The warranty of the equipment is more than 2 years. We need to provide wear parts which can be used for more than 2 years.

b. Polymer dosing pipe, press pipe, washing pipe with 304 stainless steel material is preferred.

c. All equipment materials are suitable for corrosive environment around waste water or sludge.

8. Preventive measures for equipment

All materials are suitable for corrosive environment around waste water or sludge.

a. All stainless steel parts shall be treated by acid washing and passivation, which can remove the rust and oil on the surface.

b. All carbon steel and cast iron, except stainless steel and copper alloy, should be corroded according to GB8923. The surface descaling quality reaches Sa2.5 standard. After descaling, carbon steel is sprayed with hot zinc and then painted.